Register to get 1 free article

Reveal the article below by registering for our email newsletter.

Want unlimited access? View Plans

Already have an account? Sign in

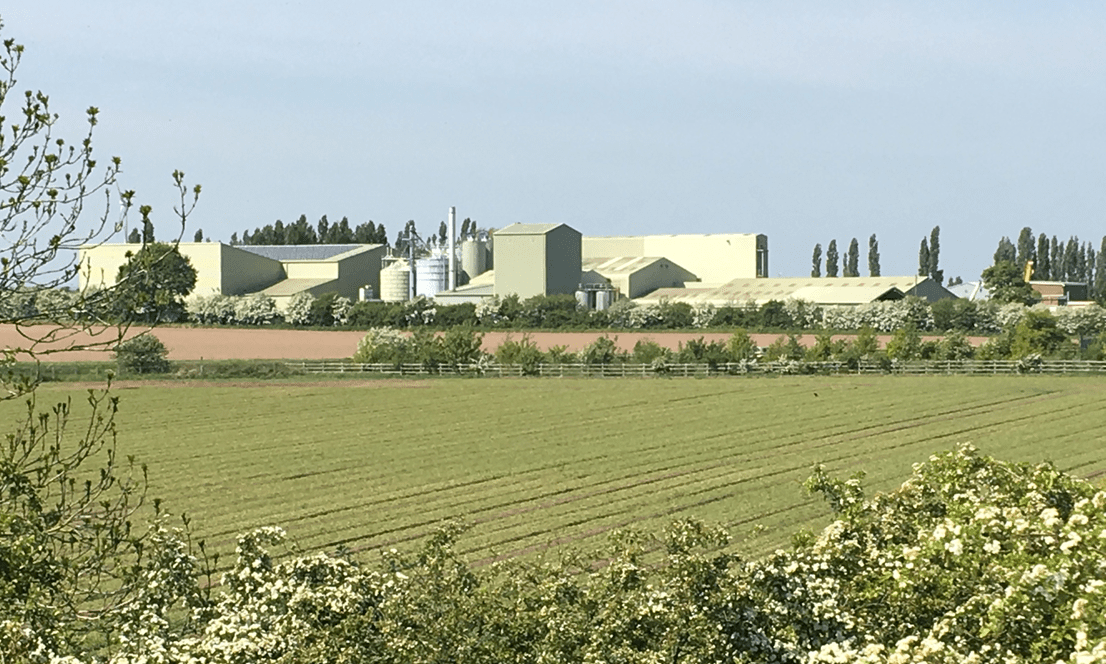

Pet food manufacturer Burgess Pet Care has completed a £3.36m five-year upgrade programme across its Yorkshire production site to increase capacity, efficiency and sustainability.

The investment supports the firm’s plans to expand its own-label manufacturing partnerships alongside its established branded portfolio, providing retailers and pet food brands with access to UK-based, sustainable production.

Upgrades at the Goole site include the installation of solar panels, new packing lines designed for recyclable materials, enhanced energy monitoring systems, new silos and refurbished offices. The company has also expanded its electric vehicle fleet.

Burgess said the changes have led to measurable improvements in throughput, material recovery and overall sustainability performance. The upgrades form part of its wider environmental strategy, which aims to reduce waste, increase recyclable packaging and lower carbon emissions across its operations.

The enhanced facilities allow Burgess to offer flexible own-label manufacturing options, including bespoke formulations, packaging and distribution, while maintaining its BRC AA rating for the fifth consecutive year.

Suzanne Moyes, deputy managing director ,said: “This investment futureproofs our operations while ensuring we can continue to deliver high-quality, sustainable products for both our own brands and our growing base of private label partners. We’ve focused on upgrades that enhance energy efficiency, improve recyclability, and expand our production capabilities to meet increasing market demand.”

“More and more of our retail and brand partners are setting ambitious sustainability goals. By investing in our site and processes, we’re making it easier for them to meet those targets without compromising on quality or efficiency.”

Peter Lancaster, head of marketing, added: “As a business, we’ve always kept animal welfare and nutrition at the heart of everything we do. We have an exceptional amount of in-house expertise including a qualified vet, a Chartered Biologist and multiple people with under graduate or postgraduate degrees in animal nutrition.

“This team of experts ensures every product we make, whether it’s for our own brands or for our private label partners, meets the same high standards of quality and care, and that means ensuring our production facilities are the very best they can be.”